Planning Forecast

We provide regular demand forecasts to help you plan production, manage your inventory, and allocate resources effectively. These forecasts reflect our current view of future demand and are an important part of how we work together to ensure a smooth and reliable supply chain.

Please remember that forecasts are for planning purposes only and are not binding purchase orders. We recommend reviewing the forecasts regularly and informing us promptly if you foresee any challenges in meeting the forecasted volumes.

Below you will find answers to common questions about forecasts. If you need further assistance, please don’t hesitate to contact your supply chain representative.

- What is a Forecast?

- A forecast is our best estimate of the demand we expect for your products over the coming months. It helps you plan production, inventory, and resources in advance to meet our needs.

- Is the Forecast a confirmed order?

- Forecasts are not binding purchase orders. They are for planning purposes only and may change based on actual customer demand and market conditions. Only purchase orders are binding commitments.

- How often is the forecast updated?

- Forecasts are updated [weekly/monthly/quarterly], and the latest version is always available in the portal. Please review it regularly to stay aligned with our current expectations

- Where can I find the forecast?

- You can view and download the latest forecast by logging into the supplier portal.

- For suppliers which are not on the portal, Forecast can be shared via planning department based on agreements

- How should I use the forecast?

- Plan your production and raw material needs.

- Schedule your capacity and workforce.

- Identify potential constraints early and inform us of any concerns.

- Why does the forecast sometimes change?

- Forecasts reflect our current market and customer demand, which can fluctuate due to seasonality, trends, and unforeseen events. We aim to provide you with the most accurate and up-to-date information possible.

- What should I do if I see an issue with the forecast?

- If you foresee any challenges in meeting the forecasted demand — such as capacity limits, lead time constraints, or material shortages — please contact your designated supply chain contact as soon as possible so we can work on a solution.

Procurement

Supplier Eligibility Criteria

The criteria for suppliers may vary depending on the nature of the business and its specific operational requirements. Different industries, products, and service models demand tailored expectations, compliance standards, and performance benchmarks. As a result, each supplier may be evaluated or managed based on distinct criteria that align with the business’s unique needs and strategic objectives.

Purchase Order (PO)

The Purchase Order (PO) serves as the official agreement between Amway and the supplier. Upon receipt, suppliers must review the PO for accuracy. If any discrepancies are found, the supplier must promptly notify the planning team to resolve the issue.

Order Management

Suppliers will be granted access to the Supplier Order Management Portal (SOMP) if they have an annual order frequency of 12 or more purchase orders.

a. No. of POs ≥ 12/year

If the frequency of Purchase Orders (POs) exceeds 12 orders per year, PO will be created through the ERP and will flow through SOMP portal, enhancing operational efficiency and minimizing manual intervention.

b. No. of POs <12 / year

If the frequency of Purchase Orders (POs) is less than 12 orders per year, PO are created/assigned by the planner manually and sent via email.

Quality

Sampling is carried out by the Quality Assurance (QA) team during the material inward process to ensure compliance with specified quality standards before acceptance into inventory.

Delivery and Logistics

In those cases where transportation will be managed by Amway. The supplier is required to provide a delivery notification at least 48 hours in advance. Certificate of Origin (COO) is the key document needed from supplier at the time of delivery.

Invoicing and Payments

Invoice Submission Guidelines – Suppliers must submit invoices as per the instructions below:

- Suppliers receiving Purchase Orders (POs) through the SOMP platform are required to submit their invoices exclusively via the SOMP portal.

- Suppliers receiving Purchase Orders (POs) via email may submit their invoices either by email or in hard copy included with the materials.

- For Services: Invoices should be submitted via email only after receiving confirmation from the user team.

- Invoice Language Requirement – All invoices must be submitted in English.

- One PO per Invoice – Each invoice must reference only one Purchase Order.

- Invoice Accuracy – Inaccurate or incomplete invoices that do not comply with the guidelines in this document may result in payment delays.

- Payment Terms – The standard payment terms are Net 60 days. Payment due dates are calculated based on the invoice date and the terms specified in the purchase order (PO). Amway will issue payment on the due date as determined by these terms.

Dispute Resolution for Payment Issues:

- The first point of contact (POC) for resolving payment-related issues will be the Buyer/Procurement team.

- If unresolved, the issue should be escalated to the Procurement Head as the second level of contact

Supplier Performance Criteria:

Supplier performance is evaluated monthly based on clearly defined criteria, which may include quality, on-time delivery and commitment to continuous improvement. These metrics are essential to ensuring a robust and dependable supply chain. Following each evaluation cycle, a performance report is shared with suppliers via email. This report aims to promote transparency, recognize strong performance, and identify areas for improvement – encouraging ongoing collaboration and shared success.

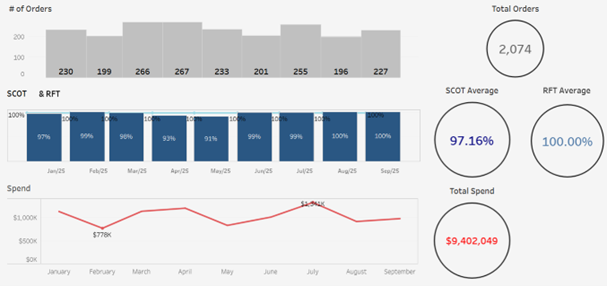

Monthly Supplier Performance shall be reported on below mentioned parameters:

- Right first time (RFT)

- Supply chain on time (SCOT)

- Total Orders

- Total Spend

The calculations for these two parameters are as below:

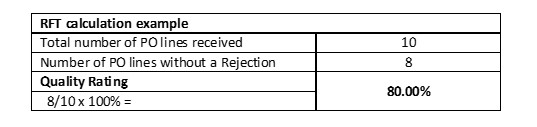

- Right First Time (RFT) Score: This measurement is quality score for the material received at a line-item level in a purchase order. Every line item in the purchase order will have a score, final score will be the simple average of all the line items received.

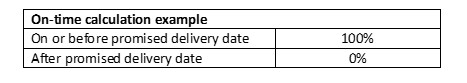

- Supply Chain On-time (SCOT): This measurement is a comparison of the “Promised Delivery Date” and “Received Date” mentioned on every purchase order line item. Any item which is received at Amway after the promised delivery date will be considered as late and will yield 0% score. Every line item mentioned in the purchased order will yield either 0% or 100% score, final score will be the simple average of all the line items received.

- Total Orders: Total Order refers to the total number of purchase orders placed with the supplier during the reporting period (typically monthly). This figure represents all confirmed orders made by our organization to the supplier, regardless of the order size, value, or delivery status. Give suppliers visibility into the volume of business they have received.

- Total Spend: Total Spend refers to the total monetary value of all purchase orders placed with the supplier during the reporting period (typically monthly). It represents the total amount our organization has committed to spending with the supplier before taxes and after any applicable discounts. Show the financial value of the business conducted with the supplier during the period.

We will also share the transaction details of all those line items based on which the score is calculated.